Delving into the realm of automotive metal cutting reveals a fascinating process that lies at the heart of automobile manufacturing. With its origins deeply rooted in craftsmanship and precision, this intricate art form has evolved over centuries to meet the demands of modern technology. In this article, we will explore the nuances of automotive metal cutting, shedding light on its historical significance and its indispensable role in shaping our contemporary world.

Ancient Origins: Tracing the Roots of Automotive Metal Cutting

To comprehend the essence of automotive metal cutting, one must embark upon a journey through time. The ancient civilizations that thrived millennia ago laid down the foundation for this craft with their rudimentary tools and unwavering dedication. From chisels meticulously crafted from stone to primitive saws fashioned from animal bones, these early artisans paved the way for future generations to refine their techniques.

As time progressed, so did mankind’s understanding of metallurgy and engineering principles. The advent of iron brought forth new possibilities for shaping metals with greater accuracy and efficiency. Blacksmiths emerged as revered figures within society, wielding hammers and anvils to forge intricate components essential for transportation.

The Renaissance: A Golden Age for Automotive Metal Cutting

It was during the Renaissance period that automotive metal cutting truly flourished as an art form. Visionaries such as Leonardo da Vinci pushed boundaries by conceptualizing innovative machines capable of transforming raw materials into functional masterpieces. Their designs incorporated gears, pulleys, and levers – precursors to today’s advanced machinery – enabling precise cuts previously unimaginable.

This era witnessed a surge in scientific inquiry alongside artistic expression; scholars sought not only aesthetic perfection but also practicality in their creations. As advancements were made in metallurgical sciences, alloys like steel and aluminum emerged, revolutionizing the automotive industry. These materials posed new challenges for metal cutters, requiring them to adapt their techniques to accommodate the unique properties of each alloy.

Modern Marvels: Automotive Metal Cutting in the Digital Age

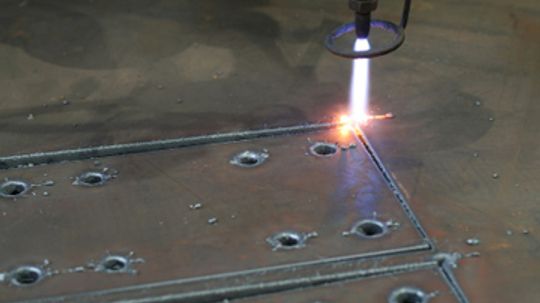

In our contemporary world, automotive metal cutting has reached unprecedented levels of precision and efficiency thanks to technological advancements. Computer Numerical Control (CNC) machines have become indispensable tools in this realm, allowing for intricate designs to be translated into flawless cuts with minimal human intervention. Laser cutting technology has also made significant strides, enabling manufacturers to achieve unparalleled accuracy while minimizing material waste.

Furthermore, automation has transformed the landscape of automotive metal cutting by streamlining production processes and reducing costs. Robots equipped with advanced sensors and algorithms work tirelessly on assembly lines, executing complex cutting tasks swiftly and flawlessly.

Closing Thoughts: A Testament to Human Ingenuity

The artistry behind automotive metal cutting is a testament to humanity’s unwavering pursuit of progress. From its humble beginnings rooted in ancient civilizations’ craftsmanship to its current state as a pinnacle of technological innovation, this discipline continues shaping our modern world. As we marvel at sleek car bodies or admire intricate engine components, let us not forget the centuries-long journey that brought us here – a journey defined by meticulous precision and an unyielding commitment towards excellence.